Our Products

Businesses in the field of medical technology have diverse requirements when it comes to products and materials. EUROFLEX offers a wide range of materials that truly convince through their innovation and quality.

Used with preference in the field of medical technology, our semi-finished products serve as a basis for implants such as vascular support (stents) and a wide variety of other flexible medical instruments.

Nitinol Tubes

Nitinol Tubes

PRODUCT INFORMATIONS

- Generation 1, 2 or 3 (HCF-High Cycle Fatigue)

- ASTM F2063 compliant

- Outside surface ground, inner surface slurry-cleaned or various options

- Tight tolerances for OD, WT and concentricity

- OD to wall ratios of up to 100 can be offered

- Defined areas for mechanical and physical properties

DIMENSIONS

Quality Stent/Heart valve XS

Outer diameter 0,06 mm up to 25,00 mm

Wall thickness/Inner diameter 0,02 mm up to 1,20 mm

Quality Catheter CQ

Outer diameter 0,20 mm up to 1,50 mm

Wall thickness/Inner diameter 0,10 mm up to 1,30 mm

Nitinol Tubes - Generation 3: HCF-SE (High Cycle Fatigue)

- Improved fatigue compared to first and second generation materials

- More options for new designs

- Higher yields

- HCF refining process

- Higher surface quality

- ASTM F2063 compliant

- Inclusion size max. 10μm, area percentage max. 0.7%

- Particle Void-Assembly (PVA) <0.01%

APPLICATIONS NITINOL-TUBES

As part of the international PRIME project, EUROFLEX offers high-performance Nitinol tubes.

Developed in close collaboration with leading industry partners, PRIME tubes are optimized for quality, performance, and availability.

Contact us to learn more about PRIME tubes.

Visit the official projet webseite: www.prime-ingot.com

Cobalt-Based-Alloys - Seamless Tubes

PRODUCT INFORMATIONS

- small grain size

- high density

- high modulus of elasticity

DIMENSIONS

OD 0,200 mm up to 30,00 mm

WT 0,025 mm up to 1,20 mm

MATERIALS

- L605

- MP35N

APPLICATIONS FOR COBALT-BASED-ALLOYS

Stainless Steel - Seamless Tubes

PRODUCT INFORMATIONS

- medical stainless steels

- excellent biocompatibility

- high elongation

- small grain and inclusion size

- good strength properties

DIMENSIONS

OD 0,200 mm up to 30,00 mm

WT 0,025 mm up to 1,20 mm

MATERIALS

Stainless steels for surgical implants:

- 316LVM

- Ni-free stainless steel, e.g. Biodur

Stainless steel for surgical instruments:

- 304

- 304L

- 321

- 17-7 PH

- 316Ti

- 316L

APPLICATIONS SEAMLESS TUBES - STAINLESS STEEL

Various metals alloys - Seamless Tubes

DIMENSIONS

OD 0,200 mm up to 10,00 mm

WT 0,025 mm up to 1,20 mm

MATERIALS

- Titan-based alloys

- Titan grade 2, ß-Titanium

- Tantalum

- Platinum alloys - Pt, Ptlr10, Ptlr20, PtW8, PtW5

- Resorbable alloys

APPLICATIONS SEAMLESS TUBES - VARIOUS METAL ALLOYS

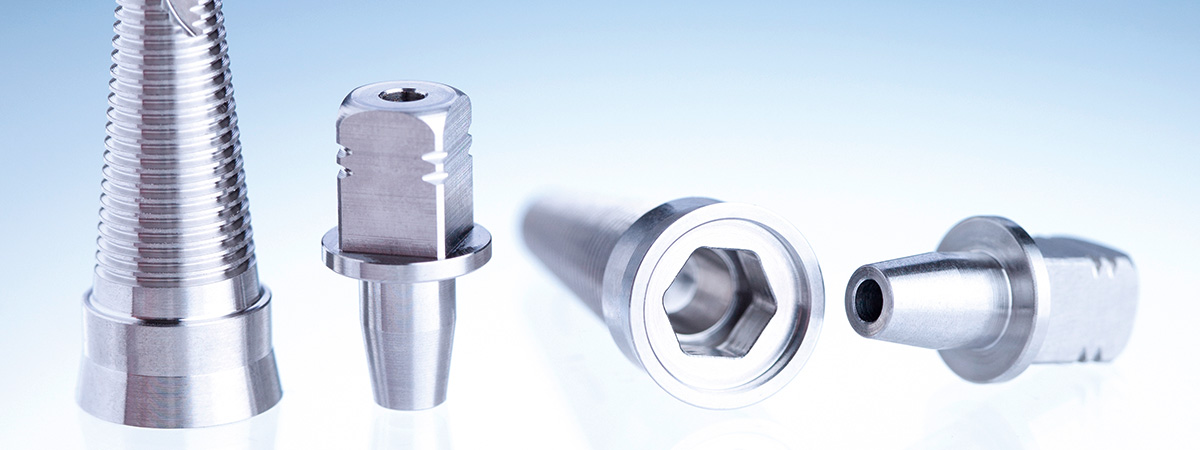

Medical components

Manufacturing Technologies

| Tubes | Nitinol / Stainless Steel / Precious Metals | OD 0,800 - 25,400 mm |

| Wires / Bars | Nitinol / Stainless Steel / Precious Metals | Ø 0,800 - 25,400 mm |

| Tubes | Nitinol / Stainless Steel | OD > 0,100 mm |

| Wires | Nitinol / Stainless Steel | Ø > 0,100 mm |

| Sheets | Nitinol / Stainless Steel | THK 0,100 - 1,000 mm |

| Tubes | Nitinol / Stainless Steel | OD 0,500 - 31,000 mm |

| Sheets | Nitinol / Stainless Steel | THK 0,100 - 1,200 mm |

| Tubes | Nitinol / Stainless Steel | OD > 0,100 mm |

| Wires / Bars | Nitinol / Stainless Steel | Ø > 0,100 mm |

| Sheets | Nitinol / Stainless Steel | THK > 0,100 mm |

| Tubes | Nitinol / Stainless Steel / further Metal Alloys | OD > 0,100 mm |

| Wires / Bars | Nitinol / Stainless Steel / further Metal Alloys | Ø > 0,100 mm |

| Sheets | Nitinol / Stainless Steel / further Metal Alloys | THK > 0,100 mm |

| Tubes | Nitinol | OD 0,100 - 3,000 mm |

| Wires | Nitinol | Ø 0,100 - 3,000 mm |

| Sheets | Nitinol | THK 0,050 - 1,000 mm |

| Tubes | Nitinol / Stainless Steel | OD 0,400 - 1,600 mm |

| Wires | Nitinol / Stainless Steel | Ø 0,400 - 1,600 mm |

| Wires | Nitinol / further Metal Alloys | Ø 0,013 - 0,250 mm | length < 1750 mm |

| Tubes | Nitinol / Stainless Steel | OD 0,400 - 1,600 mm |

| Wires | Nitinol / Stainless Steel | Ø 0,400 - 1,600 mm |

APPLICATIONS

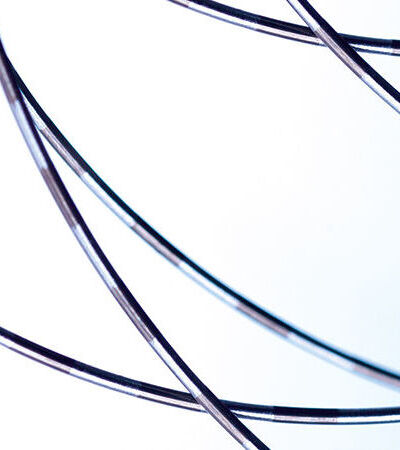

WIRES

Nitinol HCF-SE WIRES and Compounds

PRODUCT INFORMATIONS

- Nitinol HCF-SE

- with oxidized or oxid-free surface

- Improved surface quality through electro-polishing with a reel-to-reel electro-polishing system designed in-house

DIMENSIONS

diameter min. 0,025 mm

MATERIALS

- Core materials: Pt, PtW8, PtIr, Au, AG Ta

(Other material on request)

APPLICATIONS FOR ROUND WIRES

MICRO-PROFILES

PRODUCT INFORMATIONS

- reel to reel electropolishing

- In-Line process controls and automatic adjustment of parameters for maximum uniformity

- Improved surface quality through electro-polishing with a reel-to-reel electro-polishing system designed in-house

DIMENSIONS

thickness min. 0,020 mm

width up to 1,50 mm

MATERIALS

- Nitinol

- Platinum alloys

- Resorbable alloys (Mg, Zn)

- Compound materials

(Other materials on request)

APPLICATIONS MICRO-PROFILES

CONTINUOUS FLAT-ROLLED SHEET WITH OXID SURFACE

PRODUCT INFORMATIONS

- ASTM F2063 compliant

- superelastic or shape memory

- Endless process --> consistent properties

- Sandblasted or light oxide surface

- On coils or in lengths

- Natural or straight edges

- Cost savings on coils

DIMENSIONS

thickness 0,15 mm up to 1,20 mm

width up to 30,00 mm

(Other dimensions and materials on request)

APPLICATIONS